Custom Aluminium alloy casting produk deningproses pengecoran pasirlanmesin CNC.

Langkah-langkah Proses Produksi Pengecoran Pasir

1. Nggawe Pola

Pola resin utawa aluminium bakal dibutuhake kanggo proses pengecoran pasir ijo. Tanpa pola, produksi kanggo casting ora mungkin. Kadhangkala, pola kayu bisa digunakake kanggo produksi jumlah cilik, nanging kanggo produksi massal, pola resin utawa aluminium bakal luwih cocok.

2. Proses Molding

Cetakan pasir ijo bisa digawe kanthi telung cara biasane, kalebu ngecor manual, mesin ngecor lan peralatan ngecor otomatis. Molding manual minangka cara ngecor tradisional, nanging isih ana amarga kemampuan kanggo casting gedhe kanthi biaya sing luwih murah. Cara mesin ngecor bisa ngirit tenaga lan ngasilake casting kualitas sing luwih apik, nanging ora bisa ngasilake casting gedhe amarga watesan ukuran kothak wedhi.

3. wesi leleh lan pour

Leleh bisa ditindakake kanthi tungku induksi listrik frekuensi medium, sing bisa njaga kualitas apik lan stabil dibandhingake karo tungku tradisional.

4. Sand Blasting lan Grinding

Sawise casting wesi wedhi ijo sing dijupuk metu saka cetakan wedhi, padha bakal ditransfer menyang langkah sabanjure kanggo dijupuk blasting utawa dijupuk-peening kanggo mbusak wedhi lan oxide njaba bagean casting. Banjur operator bakal Cut mati, ngresiki lan tlatah sirah gating, risers, garis parting lan sudhut cetha.

Proses liyane kayata perawatan panas, mesin presisi lan perawatan permukaan bakal ditindakake yen gambar utawa pangguna pungkasan mbutuhake.

Aluminium lan wesi bisa matak lan diwutahake dening dhuwur meksa die casting, meksa kurang die casting, gravitasi casting, wedhi casting, investasi casting lanilang casting umpluk. Biasane, casting aluminium duwe bobot kurang nanging struktural rumit lan permukaan sing luwih apik.

Apa Aluminium Alloy We Cast dening Proses Sand Casting:

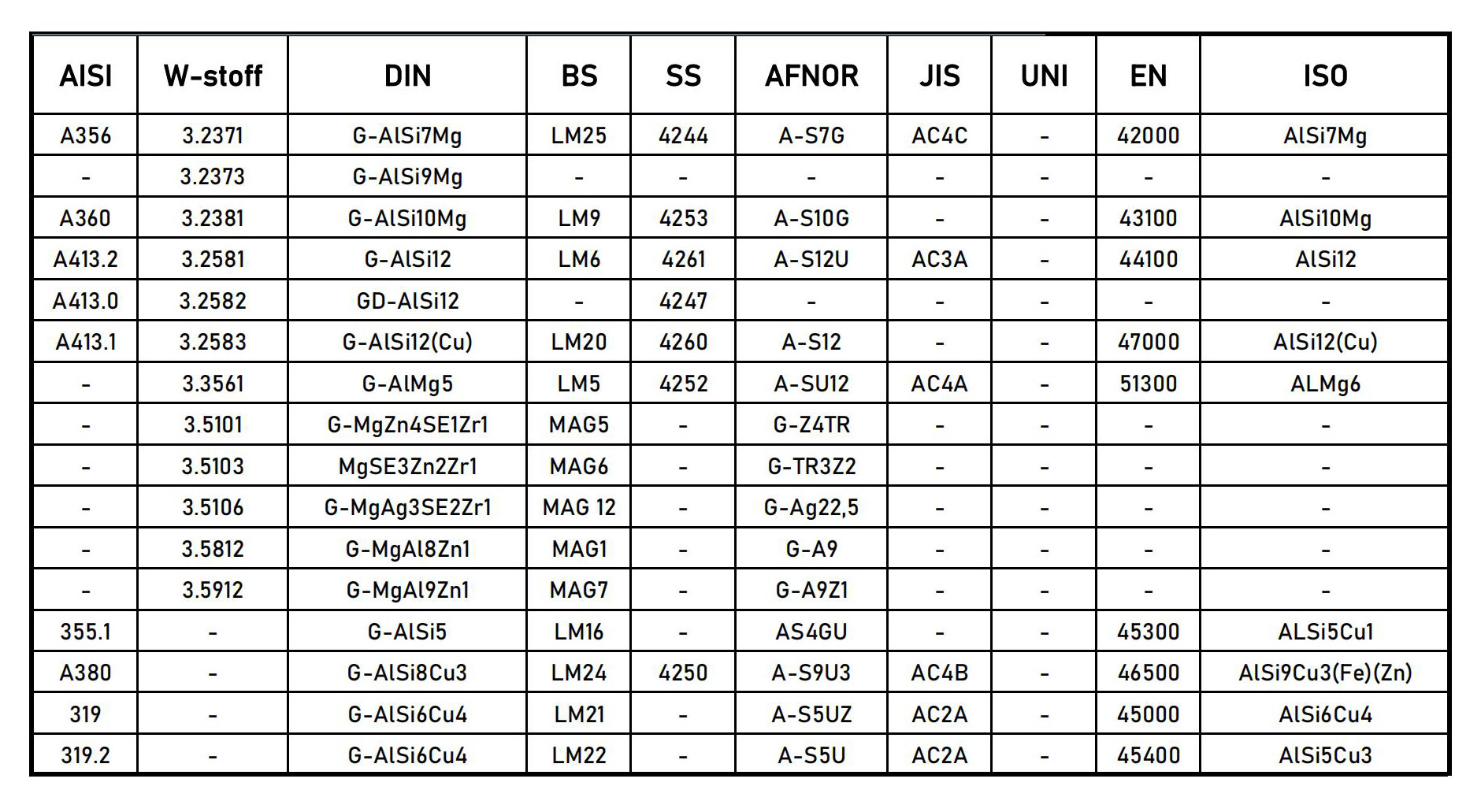

• Cast Aluminium Alloy dening China Standard: ZL101, ZL102, ZL104

• Cast Aluminium Alloy dening USA Stardard: ASTM A356, ASTM A413, ASTM A360

• Cast Aluminium Alloy dening Starndards liyane: AC3A, AC4A, AC4C, G-AlSi7Mg, G-Al12

| Manunggal | Asosiasi Aluminium | Kekerasan BHN | Kekuatan tarik pamungkas, MPa | Kekuwatan Ngasilake, MPa | Modulus elastisitas, GPa | Kekuwatan Kelelahan, MPa |

| A03550 | AA355.0 | 75-105 | 255 | 185 | 70.3 | 69.0 |

| A03600 | AA360.0 | 75.0 | 300 | 170 | 71.0 | 138.0 |

| A03800 | AA380.0 | 80.0 | 317 | 159 | 71.0 | 138.0 |

| A03830 | AA383.0 | 75.0 | 310 | 152 | / | 145.0 |

| A03840 | AA384.0 | 85.0 | 331 | 165 | / | 140.0 |

| A03900 | AA390.0 | 120.0 | 280 | 240 | 81.2 | 140.0 |

| A04130 | AA413.0 | 80.0 | 296 | 145 | 71.0 | 130.0 |

| A04430 | AA443.0 | 30-60 | 145 | 48.3 | 71.0 | / |

| A05180 | AA518.0 | 80.0 | 310 | 193 | 69.0 | 160.0 |

Kaluwihan saka Aluminium Alloy Casting:

• Kinerja casting padha karo casting baja, nanging sifat mechanical relatif nyuda liyane Ngartekno minangka kekandelan tembok mundhak.

• Ing kekandelan tembok saka castings ngirim ora gedhe banget, lan fitur struktural liyane padha karo casting baja.

• Bobot entheng nanging struktural kompleks

• Biaya casting saben kg casting aluminium luwih dhuwur tinimbang casting wesi lan baja.

• Yen diprodhuksi dening proses casting die, biaya jamur lan pola bakal luwih saka pangolahan casting liyane. Mulane, casting aluminium die casting bakal luwih cocok kanggo castings saka jumlahe nuntut gedhe.

| Komposisi Kimia Khas saka Investasi Casting Aluminium Alloy dening Specifications Amérika Lor | ||||||||||||||

| Kelas Alloy | Spesifikasi | Al | Cu | Si | Zn | Mg | Cr | Fe | Mn | Ti | Ag | Be | Ni | P |

| A356-T6 | AMS 4218 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.25-0.45 | - | 0.20 | 0.10 | 0.20 | - | -- | - | - |

| A 357 | AMS 4219 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.40-.70 | - | 0.20 | 0.10 | 0.04-0.20 | - | 0.04-0.07 | - | - |

| F 357 | AMS 4289 | Bal | 0.20 | 6.5-7.5 | 0.10 | 0.40-.70 | - | 0.10 | 0.10 | 0.04-0.20 | - | 0.002 | - | - |

| E 357 | AMS 4288 | Bal | - | 6.5-7.5 | 0.10 | 0.55-0.60 | - | 0.10 | 0.10 | 0.10-0.20 | - | 0.002 | - | - |

| A201 | AMS 4229 | Bal | 4.0-5.0 | 0.05 | - | 0.15-0.35 | - | 0.10 | 0.20-0.34 | 0.15-0.35 | 0.40-1.0 | - | - | - |

| C355 | AMS 4215 | Bal | 1.0-1.5 | 4.5-5.5 | 0.10 | 0.40-0.60 | - | 0.20 | 0,10 maks | 0.20 | - | - | - | - |

| A206 | AMS 4235 | Bal | 4.2-5.0 | .05 maks | 0,05 maks | 0.20-0.35 | - | 0,10 ma | 0.20-0.50 | 0.15-0.30 | - | - | 0,5 maks | - |

| B206 | Bal | 4.2-5.0 | .05 maks | 0,05 maks | 0.15-0.35 | - | 0,10 maks | 0.20-0.50 | 0 10 | - | - | 0,5 maks | - | |