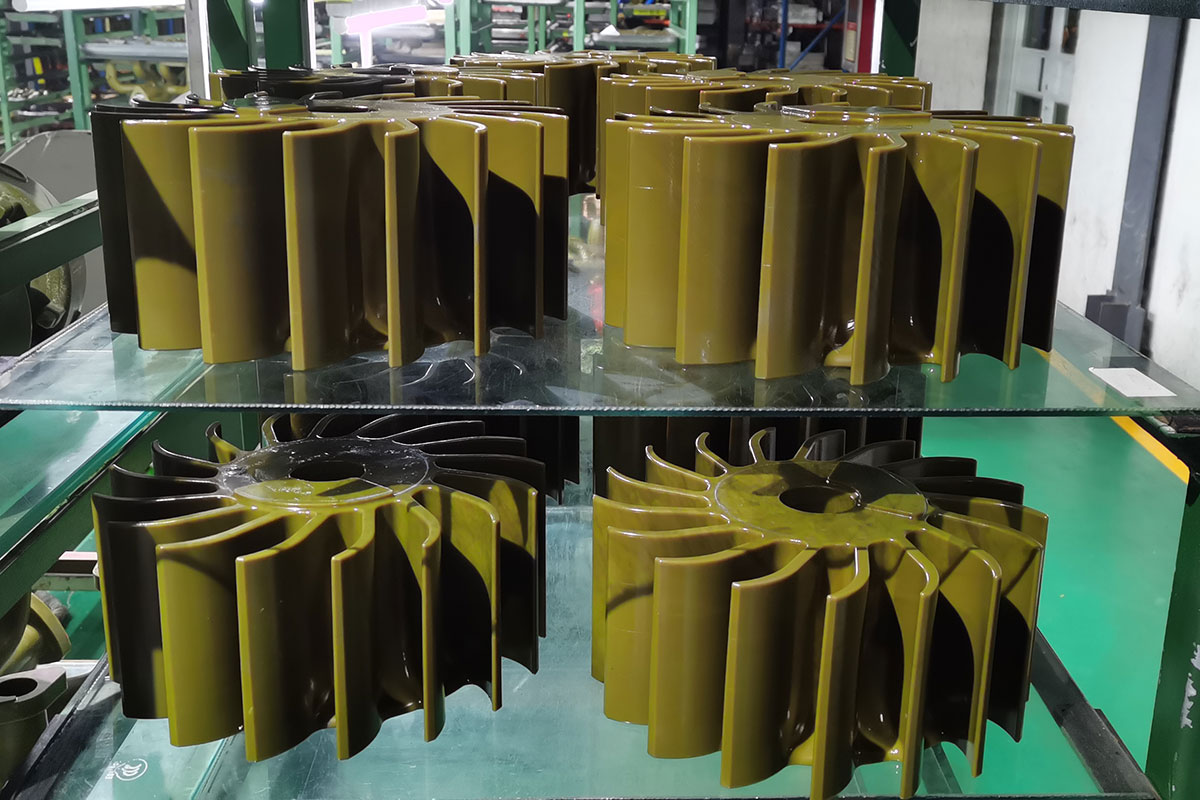

China OEM custom stainless steel impeller deningproses casting investasi lilin ilang.

Unsur paduan dasar saka sembarang casting investasi nikel-base utawa stainless steel yaiku kromium, nikel, lan molibdenum (utawa "moly"). Telung komponen iki bakal nemtokake struktur gandum casting lan sifat mekanik lan bakal dadi instrumental ing kemampuan casting kanggo pertempuran panas, nyandhang, lan karat.

Baja tahan karat nduweni kandungan kromium minimal 10,5%, dadi luwih tahan kanggo lingkungan cairan korosif lan oksidasi. Nanging, iki ora mutlak. Investasi stainless steelcasting "tahan karat" nalika digunakake ing lingkungan Cairan lan uap ngisor 1200 ° F (650 ° C) lan "tahan panas" nalika digunakake ing ndhuwur suhu iki.

Kaluwihan Komponen Casting Investasi:

- Rampung permukaan sing apik banget lan lancar

- Toleransi dimensi sing ketat.

- Bentuk sing rumit lan rumit kanthi keluwesan desain

- Kemampuan kanggo cast tembok lancip Mulane komponèn casting korek

- Pilihan saka macem-macem logam tuang lan wesi (ferrous lan non-ferrous)

- Draft ora dibutuhake ing desain cetakan.

- Ngurangi kabutuhan mesin sekunder.

- Sampah bahan sing sithik.

| Bahan kanggoInvestasi CastingProses ingRMC Foundry | |||

| kategori | Kelas China | Kelas AS | Kelas Jerman |

| Baja Tahan Karat Feritik | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Baja tahan karat martensit | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Baja tahan karat Austenitik | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 1.4406 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Baja Mn Tinggi | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Alat Baja | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Baja Tahan Panas | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nikel-Base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| alumunium Paduan | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Paduan Tembaga | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Alloy basis kobalt | UMC50, 670, Kelas 31 | 2.4778 | |

| INVESTASI CASTING TOLERANCES | |||

| inci | milimeter | ||

| ukuran | Toleransi | ukuran | Toleransi |

| Nganti 0.500 | ±.004" | Nganti 12.0 | ± 0,10 mm |

| 0.500 nganti 1.000” | ±.006" | 12.0 kanggo 25.0 | ± 0,15 mm |

| 1.000 nganti 1.500” | ±.008" | 25.0 kanggo 37.0 | ± 0,20 mm |

| 1.500 nganti 2.000" | ±.010" | 37,0 kanggo 50,0 | ± 0,25 mm |

| 2.000 nganti 2.500” | ±.012" | 50,0 kanggo 62,0 | ± 0,30 mm |

| 2.500 nganti 3.500” | ±.014" | 62,0 kanggo 87,0 | ± 0,35 mm |

| 3.500 nganti 5.000” | ±.017" | 87.0 kanggo 125.0 | ± 0,40 mm |

| 5.000 nganti 7.500” | ±.020" | 125.0 kanggo 190.0 | ± 0,50 mm |

| 7.500 nganti 10.000” | ±.022" | 190.0 kanggo 250.0 | ± 0,57 mm |

| 10.000 nganti 12.500” | ±.025" | 250,0 kanggo 312,0 | ± 0,60 mm |

| 12.500 kanggo 15.000 | ±.028" | 312,0 kanggo 375,0 | ± 0,70 mm |