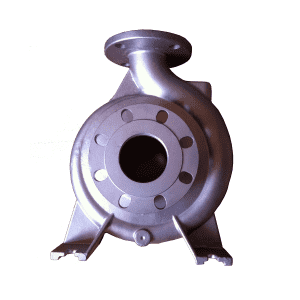

China OEM custom stainless steel castings diprodhuksi dening proses wedhi cetakan casting lan mesin CNC.

Pengecoran pasir nggunakake wedhi ijo (pasir lembab) utawa wedhi garing kanggo mbentuk sistem cetakan. Ingpengecoran pasir ijopunika proses casting paling tuwa digunakake ing sajarah. Nalika nggawe cetakan, pola sing digawe saka kayu utawa logam kudu diprodhuksi supaya bisa mbentuk rongga kothong. Logam molten banjur pour menyang growong kanggo mbentuk castings sawise cooling lan solidification. Pengecoran pasir luwih murah tinimbang proses pengecoran liyane kanggo pangembangan cetakan lan bagean casting unit. Pengecoran pasir, mesthi tegese pengecoran pasir ijo (yen ora ana katrangan khusus). Nanging, saiki, proses casting liyane uga nggunakake wedhi kanggo nggawe cetakan. Padha duwe jeneng dhewe, kayatacangkang cetakan casting, pengecoran pasir dilapisi resin furan (ora ana jinis panggang),ilang casting umpluklan casting vakum.

Kita duwe macem-macem jinis casting kanggo pilihan sampeyan. Bagéyan saka proses opsional kanggo proyek sampeyan bakal dadi pilihan proses casting sing paling cocog karo kabutuhan sampeyan. Wangun sing paling populer yaiku pengecoran pasir sing kalebu nggawe replika potongan rampung (utawa pola) sing dikompres nganggo aditif pasir lan pengikat kanggo mbentuk casting pungkasan. Pola kasebut dicopot sawise cetakan utawa kesan wis dibentuk, lan logam kasebut dikenalake liwat sistem pelari kanggo ngisi rongga kasebut. Wedhi lan logam dipisahake lan casting di resiki lan rampung kanggo dikirim menyang pelanggan.

Toleransi casting dipérang dadi Dimensional Casting Tolerances (DCT) lan Geometrical Casting Tolerances (GCT). Pengecoran kita pengin ngomong karo sampeyan yen sampeyan duwe panjaluk khusus babagan toleransi sing dibutuhake. Ing ngisor iki minangka kelas toleransi umum sing bisa ditindakake kanthi casting wedhi ijo, cetakan cetakan cangkang lan pengecoran pasir resin furan sing ora dipanggang:

✔ DCT Grade dening Green Sand Casting: CTG10 ~ CTG13

✔ DCT Grade dening Shell Mould Casting utawa Furan Resin Sand Casting: CTG8 ~ CTG12

✔ GCT Grade dening Green Sand Casting: CTG6 ~ CTG8

✔ GCT Grade dening Shell Mould Casting utawa Furan Resin Sand Casting: CTG4 ~ CTG7

Kaluwihan saka Proses Sand Casting

1- Biaya murah amarga bahan cetakan sing murah lan bisa didaur ulang lan peralatan produksi sing sederhana.

2- Bobot unit saka 0,10 kg nganti 500 kg utawa luwih gedhe.

3- Macem-macem Struktur saka jinis prasaja kanggo jinis Komplek.

4- Cocog kanggo syarat produksi saka macem-macem jumlahe.

| Bahan kanggo Proses Pengecoran Pasir ing RMC Foundry | |||

| kategori | Kelas China | Kelas AS | Kelas Jerman |

| Baja Tahan Karat Feritik | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Baja tahan karat martensit | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Baja tahan karat Austenitik | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 1.4406 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

Pengecoran Cetakan Pasir