Produk wesi cor abu-abu sing disesuaikan deningproses pengecoran cetakan pasirsaka perusahaan casting China.

Pengecoran pasir minangka proses pengecoran tradisional nanging uga modern. Iki nggunakake wedhi ijo (pasir lembab) utawa wedhi garing kanggo mbentuk sistem cetakan. Casting wedhi ijo minangka proses casting lawas sing digunakake ing sejarah. Nalika nggawe cetakan, pola sing digawe saka kayu utawa logam kudu diprodhuksi supaya bisa mbentuk rongga kothong. Logam molten banjur pour menyang growong kanggo mbentuk castings sawise cooling lan solidification. Pengecoran pasir luwih murah tinimbang proses pengecoran liyane kanggo pangembangan cetakan lan bagean casting unit. Pengecoran pasir, mesthi tegese pengecoran pasir ijo (yen ora ana katrangan khusus). Nanging, saiki, proses casting liyane uga nggunakake wedhi kanggo nggawe cetakan. Dheweke duwe jeneng dhewe, kayata casting cetakan cangkang, casting pasir dilapisi resin furan (ora ana jinis panggang), casting busa sing ilang lan pengecoran vakum.

Keuntungan saka Sand Casting:

✔ Biaya sing luwih murah amarga bahan cetakan sing murah lan bisa didaur ulang lan peralatan produksi sing sederhana.

✔ Bobot unit akeh saka 0,10 kg nganti 500 kg utawa luwih gedhe.

✔ Macem-macem Struktur saka jinis prasaja nganti jinis kompleks.

✔ Cocog kanggo syarat produksi saka macem-macem jumlah.

| Kapabilitas Sand Casting ing RMC Foundry | ||

| Katrangan | Molding kanthi tangan | Molding dening Mesin Otomatis |

| Max ukuran Castings | 1.500 mm × 1000 mm × 500 mm | 1.000 mm × 800 mm × 500 mm |

| Casting Bobot Range | 0,5 kg - 1.000 kg | 0,5 kg - 500 kg |

| Kapasitas taunan | 5.000 ton - 6.000 ton | 8.000 ton - 10.000 ton |

| Toleransi Casting | On Request or Standard (ISO8062-2013 utawa GB/T 6414-1999) | |

| Bahan Molding | Pasir Ijo, Pasir Dilapisi Resin | |

| Casting Metal & Alloys | Wesi Abu-abu, Besi Ulet, Baja Tuang, Baja Tahan Karat, Paduan Paduan, Kuningan, Perunggu...dll. | |

Toleransi sing digayuh pasir:

Toleransi casting dipérang dadi Dimensional Casting Tolerances (DCT) lan Geometrical Casting Tolerances (GCT). Pengecoran kita pengin ngomong karo sampeyan yen sampeyan duwe panjaluk khusus babagan toleransi sing dibutuhake. Ing ngisor iki minangka kelas toleransi umum sing bisa ditindakake kanthi casting wedhi ijo, cetakan cetakan cangkang lan pengecoran pasir resin furan sing ora dipanggang:

✔ DCT Grade dening Green Sand Casting: CTG10 ~ CTG13

✔ DCT Grade dening Shell Mould Casting utawa Furan Resin Sand Casting: CTG8 ~ CTG12

✔ GCT Grade dening Green Sand Casting: CTG6 ~ CTG8

✔ GCT Grade dening Shell Mould Casting utawa Furan Resin Sand Casting: CTG4 ~ CTG7

| Metal & Alloys Grade kanggo Sand Casting Proses | |

| Metal & Alloys | Kelas Popular |

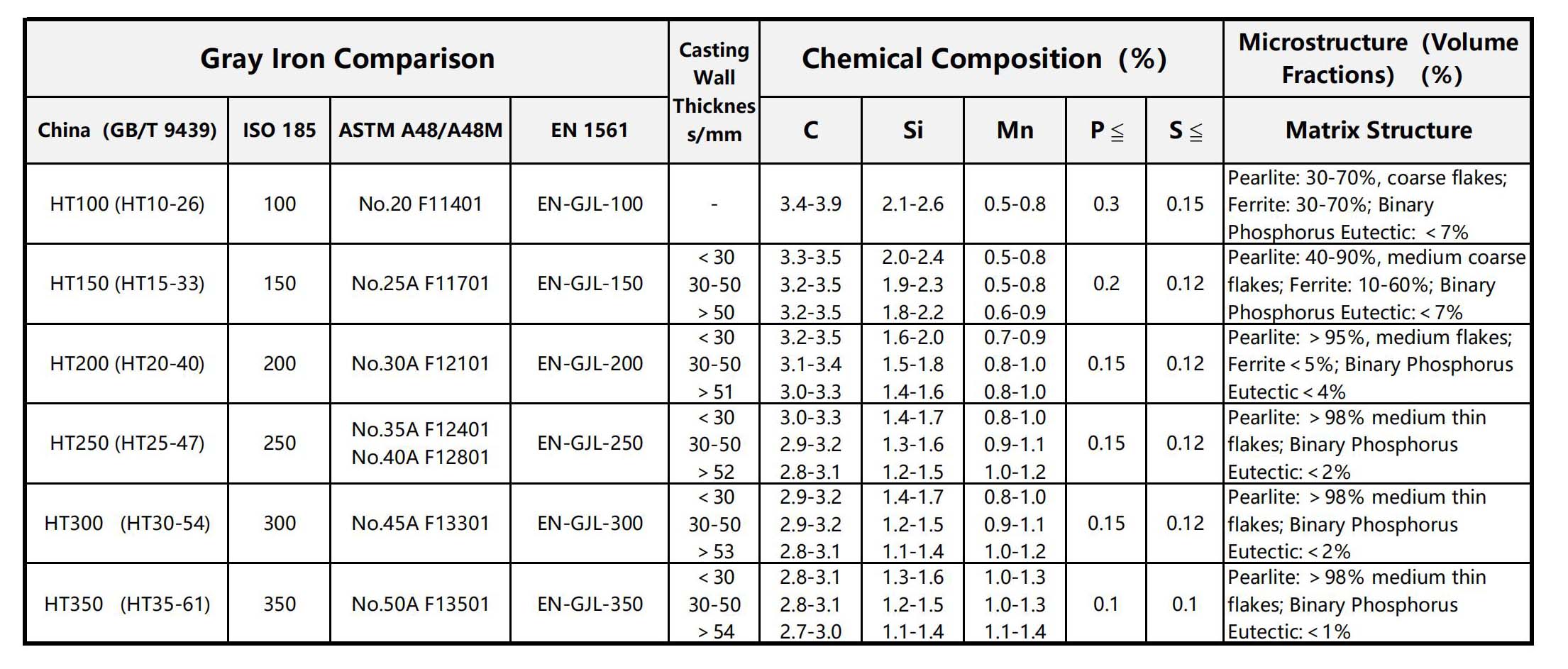

| Wesi Cast Gray | GG10~GG40; GJL-100 ~ GJL-350; |

| Besi tuang ulet (nodualar). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Baja Karbon | C20, C25, C30, C45 |

| Baja Paduan | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Baja tahan karat | Baja Tahan Karat Feritik, Baja Tahan Karat Martensit, Baja Tahan Karat Austenitik, Baja Tahan Karat Pengerasan Presipitasi, Baja Tahan Karat Dupleks |

| Paduan Aluminium | ASTM A356, ASTM A413, ASTM A360 |

| Paduan Tembaga / Kuningan | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standar: ASTM, SAE, AISI, GOST, DIN, EN, ISO, lan GB | |

Custom Sand Castings saka Casting Iron

-

Gray Casting Wesi Sand Casting Product

-

Gray Cast Iron Shell Casting Product

-

OEM Gray Casting wesi

-

Paduan Baja Resin Dilapisi Pasir Casting Crankshaft

-

Casting Pasir Baja Paduan

-

Bagian Truk Baja Paduan dening Pengecoran Pasir lan CNC...

-

Perusahaan Pengecoran Pasir Baja Karbon

-

Pengecoran Pasir Baja

-

Aluminium Alloy Sand Casting