China OEM produk baja karbon khusus casting deningproses casting investasi lilin ilang.

| Cast Carbon Steel Grade Comparison | |||||||||||

| Ora. | Cina | Jepang | USA | ISO | Jerman | Prancis | Rusia гост | Swedia SS | Inggris | ||

| GB | JIS | ASTM | UNS | DIN | W-Nr. | NF | BS | ||||

| 1 | ZG200-400 (ZG15) | SC410 (SC42) | 415-205 (60-30) | J03000 | 200-400 | GS-38 | 1.0416 | - | 15л | 1306 | - |

| 2 | ZG230-450 (ZG25) | SC450 (SC46) | 450-240 965-35) | J03101 | 230-450 | GS-45 | 1.0446 | GE230 | 25л | 1305 | A1 |

| 3 | ZG270-500 (ZG35) | SC480 (SC49) | 485-275 (70-40) | J02501 | 270-480 | GS-52 | 1.0552 | GE280 | 35л | 1505 | A2 |

| 4 | ZG310-570 (ZG45) | SCC5 | (80-40) | J05002 | - | GS-60 | 1.0558 | GE320 | 45л | 1606 | - |

| 5 | ZG340-640 (ZG55) | - | - | J05000 | 340-550 | - | - | GE370 | - | - | A5 |

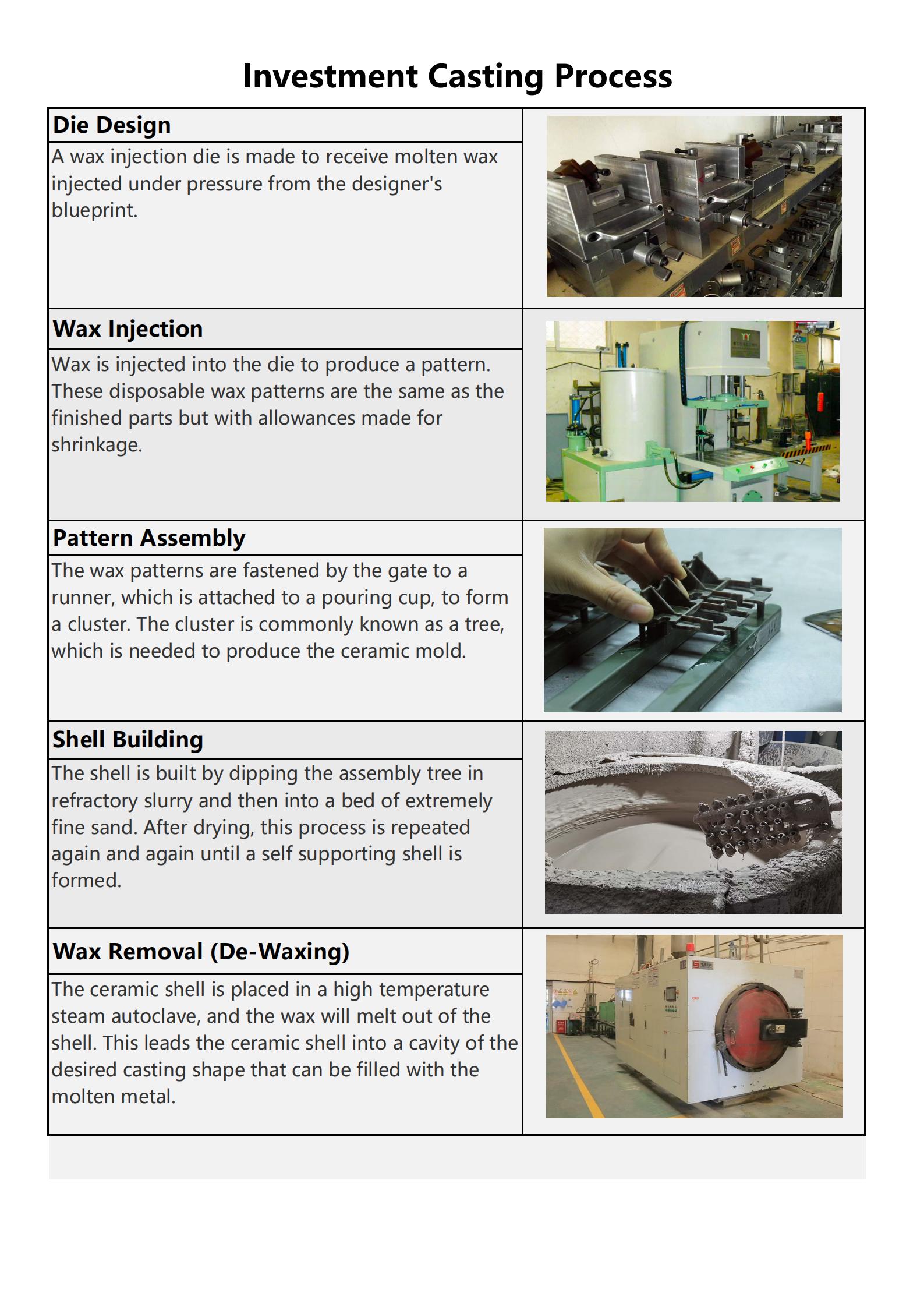

Kapabilitas Pengecoran Pengecoran Investasi:

• Ukuran Maks: 1.000 mm × 800 mm × 500 mm

• Bobot Range: 0,5 kg - 100 kg

• Kapasitas taunan: 2.000 ton

• Bahan Bond kanggo Bangunan Shell: Sol silika, Kaca banyu lan campurane.

• Toleransi: On Request.

Kaluwihan Komponen Casting Investasi:

- Rampung permukaan sing apik banget lan lancar

- Toleransi dimensi sing ketat.

- Bentuk sing rumit lan rumit kanthi keluwesan desain

- Kemampuan kanggo cast tembok lancip Mulane komponèn casting korek

- Pilihan saka macem-macem logam tuang lan wesi (ferrous lan non-ferrous)

- Draft ora dibutuhake ing desain cetakan.

- Ngurangi kabutuhan mesin sekunder.

- Sampah bahan sing sithik.

| Bahan kanggoInvestasi CastingProses ing RMC Foundry | |||

| kategori | Kelas China | Kelas AS | Kelas Jerman |

| Baja Tahan Karat Feritik | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Baja tahan karat martensit | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Baja tahan karat Austenitik | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 1.4406 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Baja Mn Tinggi | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Alat Baja | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Baja Tahan Panas | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nikel-Base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| alumunium Paduan | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Paduan Tembaga | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Alloy basis kobalt | UMC50, 670, Kelas 31 | 2.4778 | |

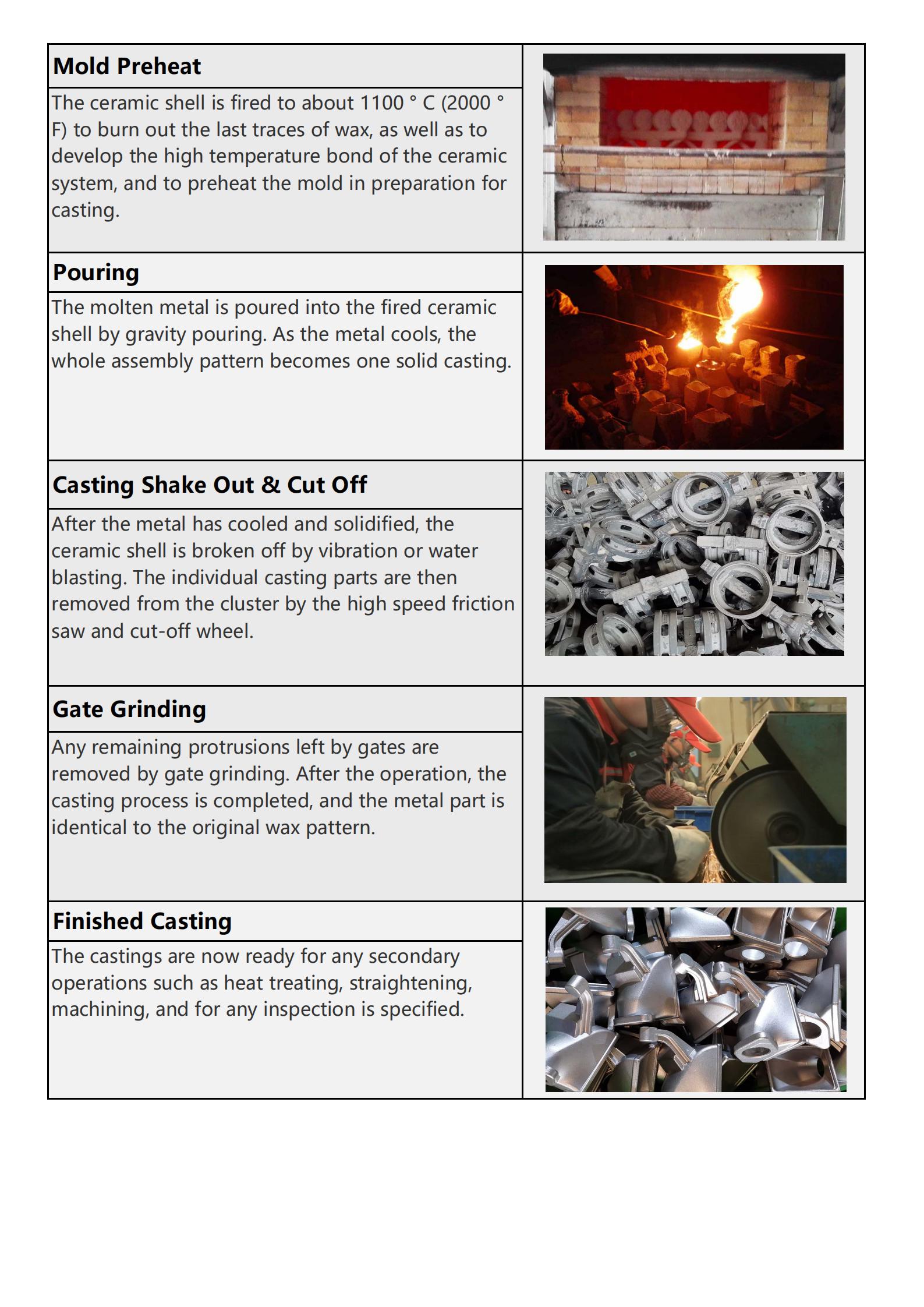

| INVESTASI CASTING TOLERANCES | |||

| inci | milimeter | ||

| ukuran | Toleransi | ukuran | Toleransi |

| Nganti 0.500 | ±.004" | Nganti 12.0 | ± 0,10 mm |

| 0.500 nganti 1.000” | ±.006" | 12.0 kanggo 25.0 | ± 0,15 mm |

| 1.000 nganti 1.500” | ±.008" | 25.0 kanggo 37.0 | ± 0,20 mm |

| 1.500 nganti 2.000" | ±.010" | 37,0 kanggo 50,0 | ± 0,25 mm |

| 2.000 nganti 2.500” | ±.012" | 50,0 kanggo 62,0 | ± 0,30 mm |

| 2.500 nganti 3.500” | ±.014" | 62,0 kanggo 87,0 | ± 0,35 mm |

| 3.500 nganti 5.000” | ±.017" | 87.0 kanggo 125.0 | ± 0,40 mm |

| 5.000 nganti 7.500” | ±.020" | 125.0 kanggo 190.0 | ± 0,50 mm |

| 7.500 nganti 10.000” | ±.022" | 190.0 kanggo 250.0 | ± 0,57 mm |

| 10.000 nganti 12.500” | ±.025" | 250,0 kanggo 312,0 | ± 0,60 mm |

| 12.500 kanggo 15.000 | ±.028" | 312,0 kanggo 375,0 | ± 0,70 mm |