OEM custom stainless steel casting awak pump karoLayanan mesin CNClan layanan perawatan panas saka pengecoran pengecoran China.

Baja tahan karat nduweni kandungan Cr minimal 11,5%, lan unsur paduan liyane kayata Ni lan Mo, dadi luwih tahan kanggo lingkungan cairan korosif lan oksidasi. Nduwe kinerja tahan karat lan tahan nyandhang, nyedhiyakake kemampuan mesin sing apik, lan uga misuwur kanthi tampilan estetis.Casting investasi stainless steel"tahan korosi" nalika digunakake ing lingkungan cair lan uap ing ngisor 1200 ° F (650 ° C) lan "tahan panas" yen digunakake ing ndhuwur suhu iki.

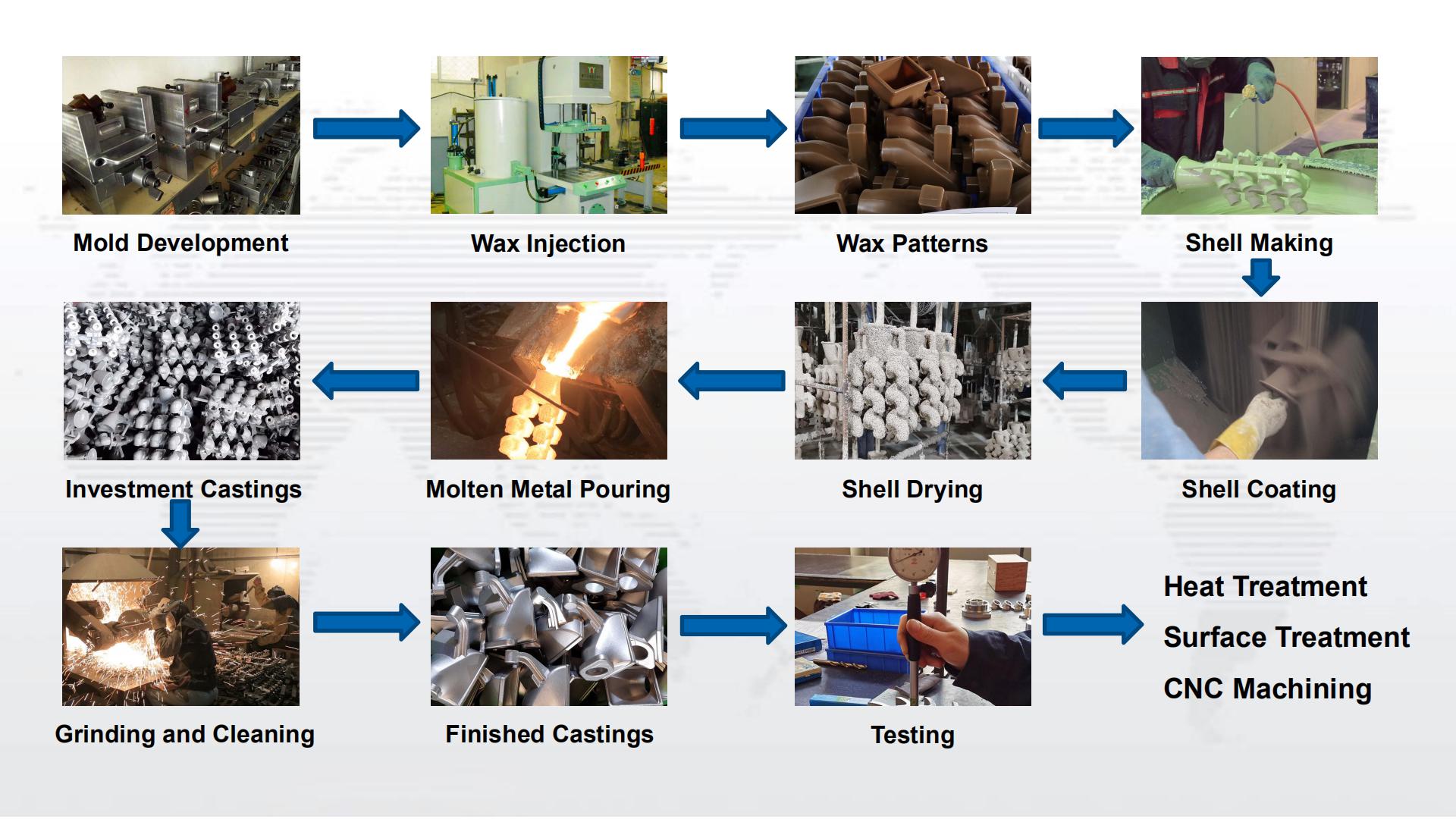

Proses casting silika sol minangka sing utamaproses pengecoran investasi bajasaka pengecoran casting investasi RMC. Kita wis ngembangake teknologi bahan adesif anyar kanggo entuk bahan adesif sing luwih ekonomis lan efektif kanggo mbangun cangkang slurry. Iku gaya akeh banget sing silika sol casting proses nggantèkaké kasar inferior proses kaca banyu, utamané kanggo stainless steel casting lancasting baja paduan. Kejabi materi ngecor inovatif, proses casting sol silika uga wis inovasi kanggo akeh steadier lan kurang panas ngembangaken.

| Bahan kanggo Proses Casting Investasi ing RMC Foundry

| |||

| kategori | Kelas China | Kelas AS | Kelas Jerman |

| Baja Tahan Karat Feritik | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Baja tahan karat martensit | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Baja tahan karat Austenitik | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 1.4406 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Baja Mn Tinggi | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Alat Baja | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Baja Tahan Panas | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nikel-Base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| alumunium Paduan | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Paduan Tembaga | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Alloy basis kobalt | UMC50, 670, Kelas 31 | 2.4778 | |